Powder Metallurgy Ti64ELI Substrate lessen the potential for buckling

Recent one decade, Metal Additive Manufacturing(MAM) has pulled off great popularity. Whereas, there is hidden trouble which is haunting the MAM engineers and industry, the thermal buckling ventures.

With regard to the requirements of MAM substrate, wrought standard, like ASTM, AMS or ISO, is the only requirement for suppliers. Unfortunately, buckling phenomena occur from time to time. The unpleasant buckling, especially titanium substrate, could inflict irreversible damage on building elaborate components. Every engineer would like to flinch such kind of unnecessary trouble.

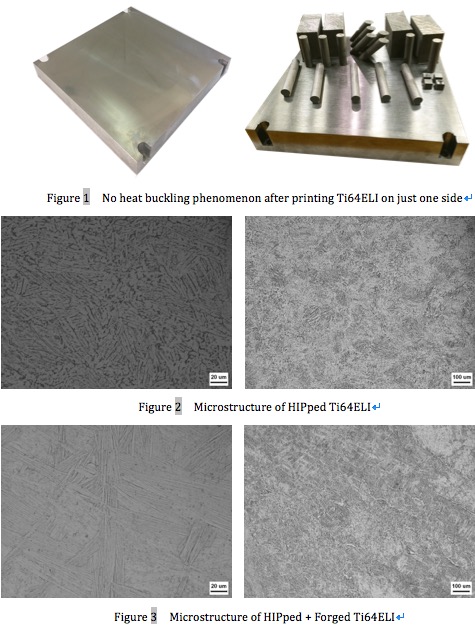

Figure 1 illustrates the substrate with similar EOS dimensions 252*252*25. Additionally, several testing compacts were built on half of substrate for the purpose of heat buckling examination. The caliber of HIPped plus forged substrate didn’t bend at all. Figure 2 displays microstructures of HIPped Ti64ELI substrate with the density 4.377 g/cm3. Figure 3 shows microstructures of HIPped plus forged substrate of which the density measure 4.399 g/cm3. Among numerous mechanical processes, HIP well is renowned for the characteristic of isotropy, namely having uniform physical properties in all directions. Furthermore, isotropy is beneficial to heat conductivity, even for titanium with poor thermal properties. As long as there is no hot rolling in the course of manufacturing, precision forged incurs little negative effect on isotropy.

Thanks for your time. Anything interesting, welcome to contact us.

Email: market@c-semt.com, gt@c-semt.com

Tel: +0086 029 86261802

Navigation

Follow Us